We specialize in

Cost Effective Solutions of

System Integration

Catering to Test, Measurement & Control Solutions

and LabVIEW Software Development

We specialize in

Cost Effective Solutions of

System Integration

Catering to Test, Measurement & Control Solutions

and LabVIEW Software Development

Innovation

in your need

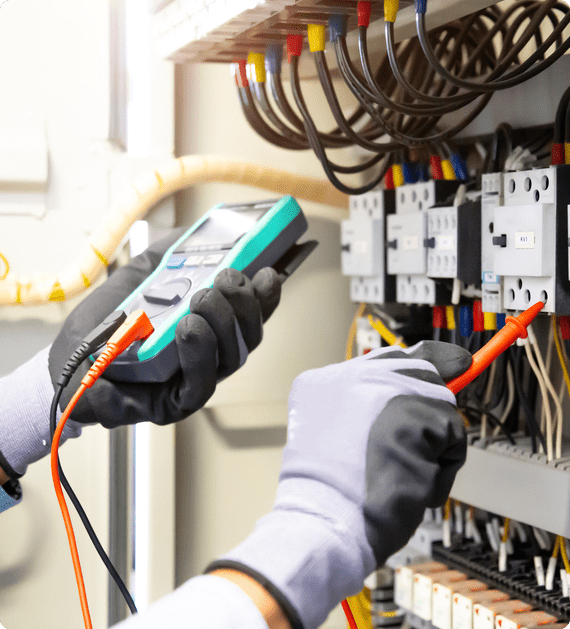

TMCS is a leading service provider of test and measurement solutions for nearly a decade. We cater to a diverse set of industries including Automotive, EV, Aero Defense, Engineering, Oil and Gas, Steel, and Pharmaceutical. Our automotive industry offerings include HIL (hardware in loop), EOL (End of Line), ATEs (Automated Test Equipment), Panel engineering solutions, NI LabVIEW based Data Acquisition systems and software development services. We offer development and V&V (Validation and Verification) to Aerospace & Defense. At TMCS, we believe in competent skills, collaborative approach, effective consultation aided by detailed planning that can fulfil your requirement with no or minimum obstacles.

Advanced Solutions for Every Industry

Automotive

TMCS Caters to the automotive industry requirements with various tests like Hardware in Loop (HIL) Performance, EOL, Production and Embedded software tests, and Data Logging systems. Vehicle testing and validation….Read More

Aerospace Defense

With customizable off the shelf platforms and systems TMCS serves Aero defense sector with verification and validation systems , Modular Automated Test Equipment for R&D as well as production .Electromechanical set ups, control systems… Read More

Engineering Service Provider

Engineering service providers rely on test systems to deliver comprehensive testing and validation to their clients TMCS helps these companies for test fixture design, control panel engineering ,data acquisition and monitoring… Read More

Power Electronics

Using hardware platforms such as NI PXI, Compact DAQ we perform testing and validation for Motor drive , inverter etc., Design and Simulation, Power Quality Analysis and pc based data acquisition This includes measuring parameters such as voltage…. Read More

EV

about TMCS

Incepted in the year 2013, We are specialized in developing customized automated test equipment to meet customers’ distinct requirements, which include commissioning industry standard automation, measurement hardware, and software, data acquisition, and control systems. This enables the customer to deliver state of art technological solutions. The Company stands for engineering R&D excellence, dependability, and innovations.

Equipped with extensive experience, the work at TMCS is led by engineers who are nifty with analyzing needs, conceptualizing designs, and building formats that are customized for specific requirements observed across various sectors.

VISION

MISSION

Our Partners

Working in the diversified sectors like automotive , process, Defence, TMCS has joined hands with domain experts with the aim of serving the clients in the best possible way to help them to achieve their goals.

Our solutions

TMCS Caters to the automotive industry requirements with various tests like, Hardware in Loop (HIL) Performance, EOL, Production and Embedded software tests, Data Logging systems. Vehicle testing and validation systems for , Endurance, Durability, performance checking Automotive segment is classified based on the applications served e.g., Body and Chassis, Active Safety, Powertrain, infotainment.