Automotive Industries

Case studies

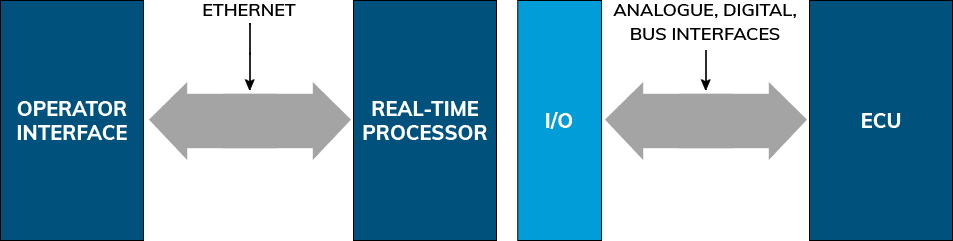

1. HIL (Hardware in Loop)

1. Software will simulate the control system to stimulate the DUT.

2. DUT is interfaced with vehicle ECU via CANFD interface.

1. Multiple device Communication

2. Automotive Diagnostic

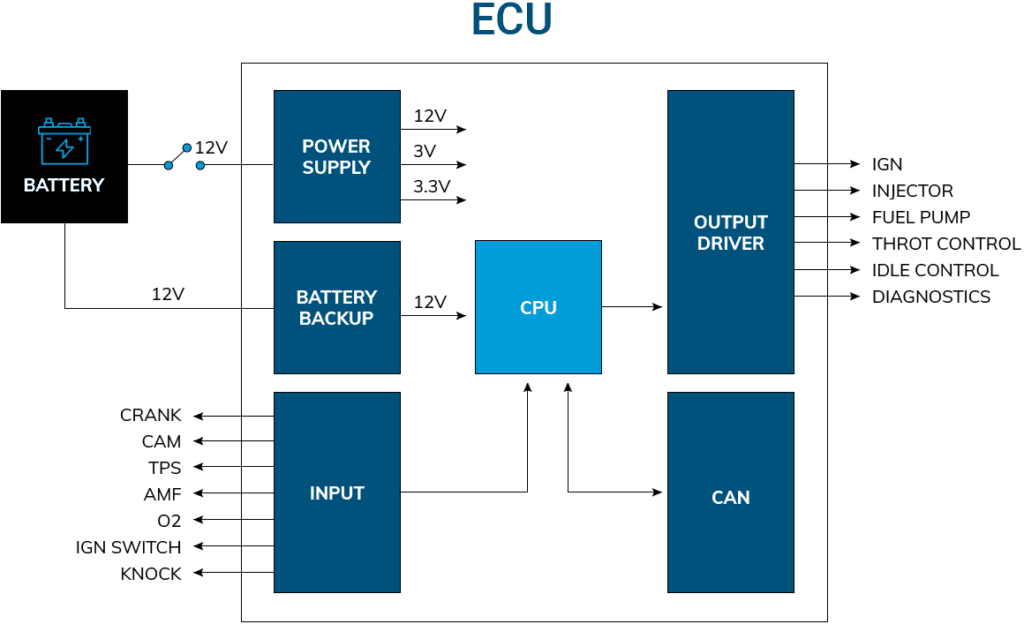

2. ECU (Electronic Control Unit)

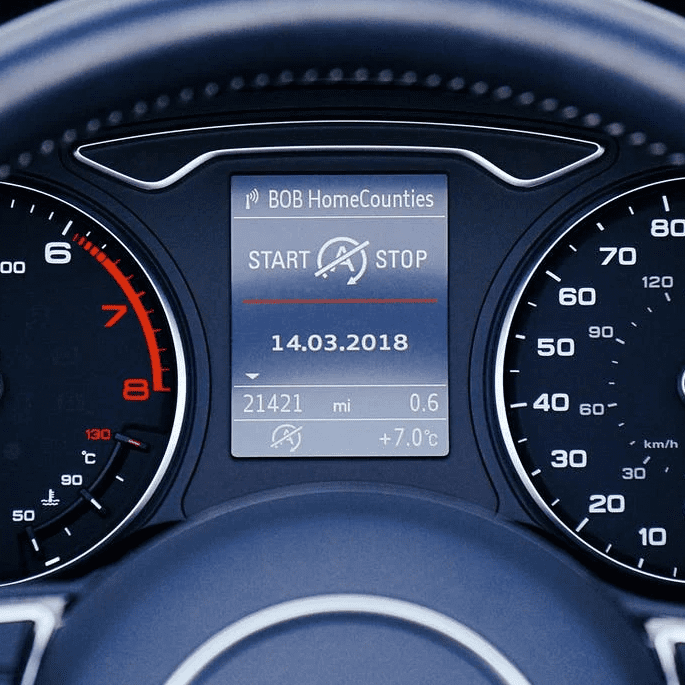

3. Instrument Cluster Tester

• Ability to turn ON and turn OFF sinking & source LEDs

• Ability to generate square wave of variable frequency.

• Simulation of test sequence in software.

• Provision for future expansion.

Application:

System will be used for performance and endurance test of auto-clusters. In the end of line functional testing of instrument clusters, various condition like speed, engine RPM, fuel tank level etc. were simulated through hardware and were applied to the respective pins of cluster and its behaviour to these input were noted. The speedometer & Tachometer indications are checked & these readings are within acceptable limit or not is checked, Checking of fuel gauge and temperature gauge indications, checking of tell-tale lamp conditions CAN Communication Protocol was used.

Conclusion:

The test system blended properly with the production flow because of the highly reliable NI hardware and the user-friendly test software.

The customer was not only able to speed up the testing process and bring down defective clusters shipped to zero but was also able to use the data from the test bench to fine tune the production process. All this was possible at one-fourth the cost of a ready to use tester because of the configurable solution offered through the Virtual Instrumentation approach.

Related solutions

ATE

EOL

DAQ

LV

Panel Engineering

IIOT

ATE

ATE

Automated Test Equipment (ATE) is a machine designed for performing tests on multiple devices known as devices under test (DUT). An ATE utilizes control systems and automated information technology for performing tests that quantify and calculate a DUT in a timely manner. ATE testing is usually used in Automotive tests, wireless communication and radar as well as electronic component manufacturing. TMCS specialises in integration of offering complete system and sub-systems.

EOL

EOL (End of Line)

End-of-line Tester (EOL) systems can measure and check the functionality of automotive electronic control units, mechanical parts and related systems. Key factors considered are high test quantity, test completion and low system with upgrade costs.

DAQ

DAQ (Data Acquisition System)

National Instruments (NI DAQ) hardware based systems can be used to monitor and record various parameters during vehicle testing, such as engine performance, emissions, temperature, pressure, and vibration. DAQ systems can monitor and record data during these tests, such as load, stress, strain, and temperature measurements, to assess the durability and reliability of the components.

LV

LV (LabVIEW Development Services)

National Instruments is a technology pioneer and market leader in virtual instrumentation, a game-changing concept that has transformed the way engineers and scientists in industry, government, and academia approach measurement and automation.

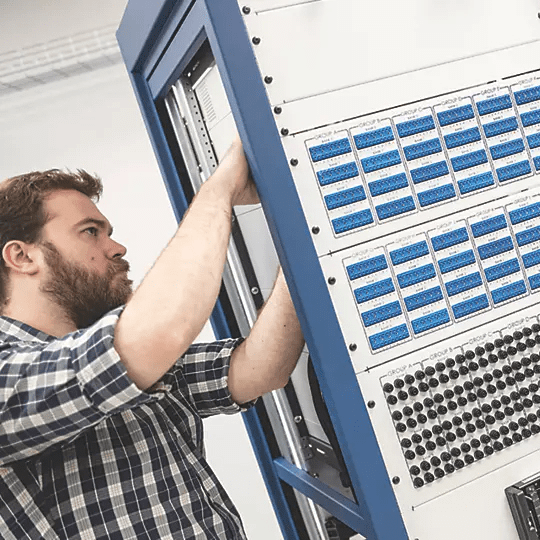

Panel Engineering

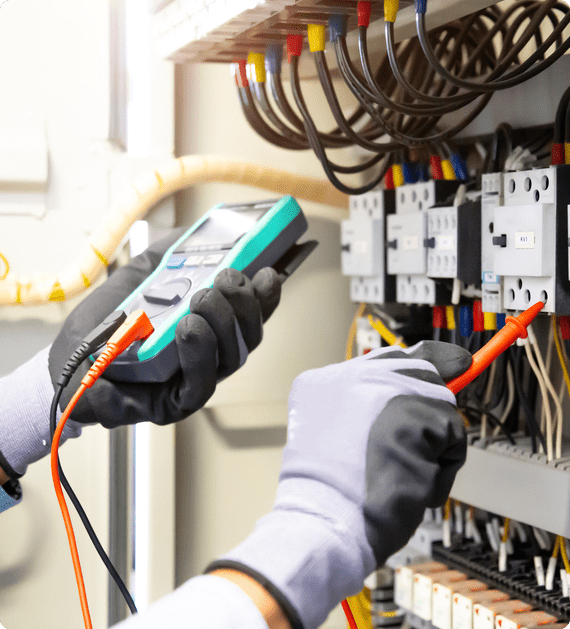

Panel Engineering

Our panel range is available with different specifications in order to meet diverse requirements of the industry like Electrical Panel, control panel, power panel. Panels are designed for convenient layout and reliable wired interconnections between internal and external components.

IIOT